Meeraner Dampfkesselbau GmbH belongs to the Premonor Group.

-

Englisch

Englisch

The MEERANERS

Welcome to the MEERANERS.

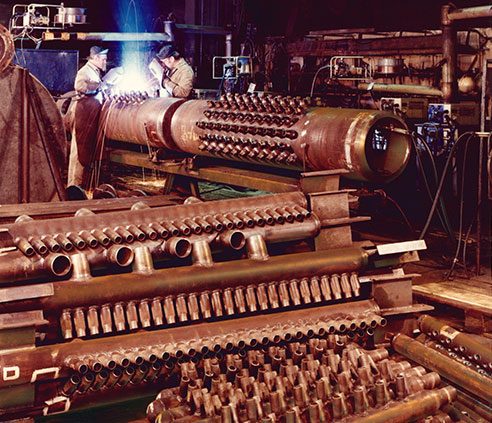

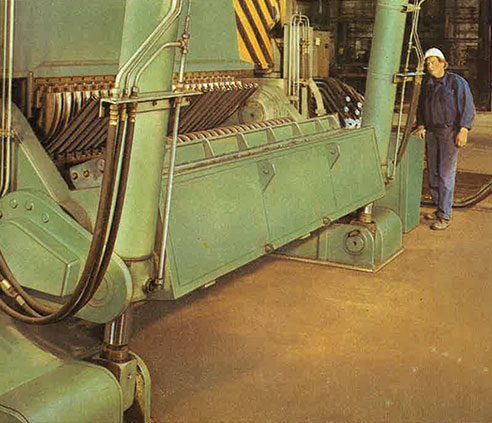

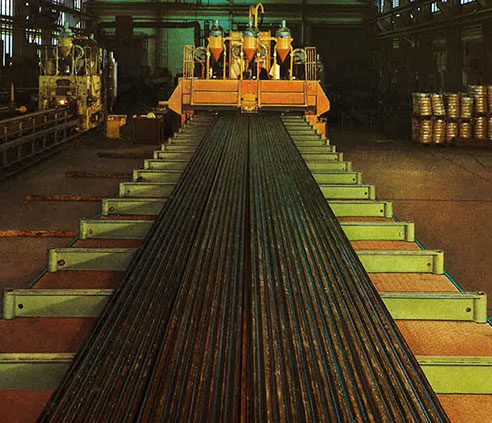

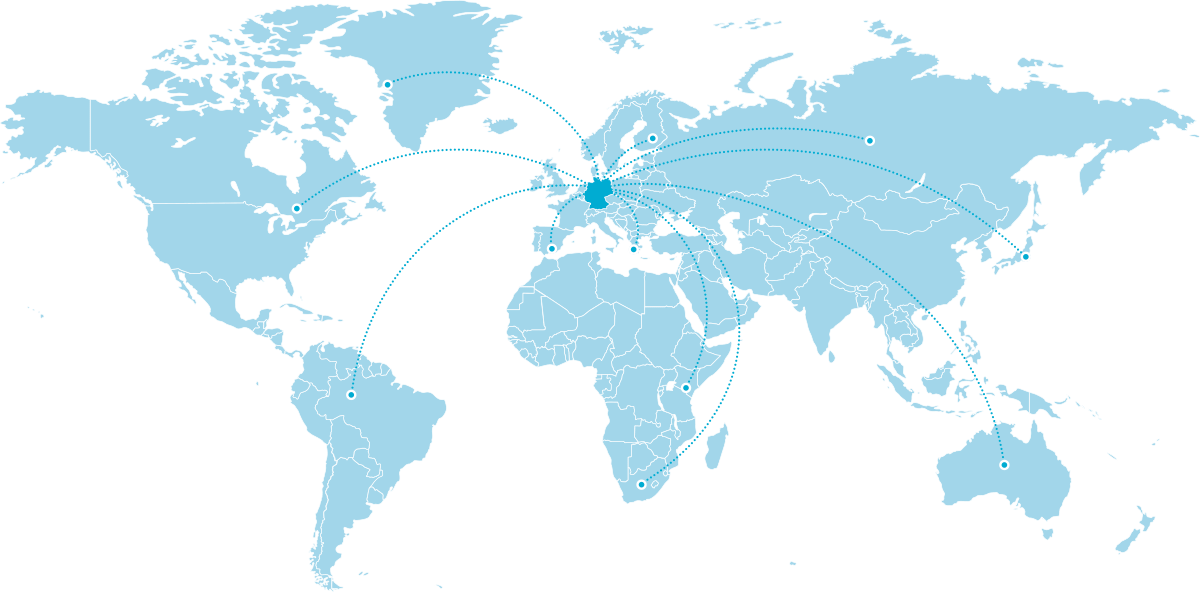

Great ideas as a powerful driving force: We have always focussed on energy. There are more than 150 years between the first small, riveted steam boilers and the current production of complex pressure parts. Much expertise and experience. And one of the reasons, why pressure parts and components from MEERANER Dampfkesselbau work in power plants and industrial plants all around the world – reliably and durably.

Furthermore, we ensure consistent original MEERANER quality with our service and maintenance services. We think outside the box: We do not only train our junior staff in our academy, but also offer welding courses at the highest level for our customers. And the many new challenges in the area of energy generation and industry? We consider these as opportunities.

Guiding principle

Our quality principles.

Fundamental values

Fairness, tolerance, integrity and responsibility towards our employees, partners and customers: We are guided by these fundamental values every day. They are based on mutual respect, transparency and honesty. They also include the issues of occupational safety, environmental protection and combating corruption, of course.

Customer orientation

Absolute reliability, loyalty and long-term customer benefits are as important for us as the most stringent safety standards and maximum quality – all the processes at MEERANER Dampfkesselbau are intended to meet these requirements. Only in this way it is possible for us to guarantee the delivery reliability, commitment and reliability our customers appreciate in us.

Responsibility

We take our social and ecological responsibility seriously. This also includes the careful use of resources and the respectful treatment of the environment, as well as a cooperative company structure based on respect and trust. For us, responsibility also means to avoid wastefulness of any kind.

Employees

We are MEERANER Dampfkesselbau: a strong, competent team which acts cross-functionally, purposefully and socially. The support and development of each team member are part of our self-perception as a learning company. And together, we bring many things forward: This is enabled by flat hierarchies and much individual responsibility.

History

As an established company with a long history, we know where we come from, where we are and where we want to be. Accordingly, our objective is to convince with experienced employees, outstanding quality and competence – on a regional level as well as throughout the world.

History

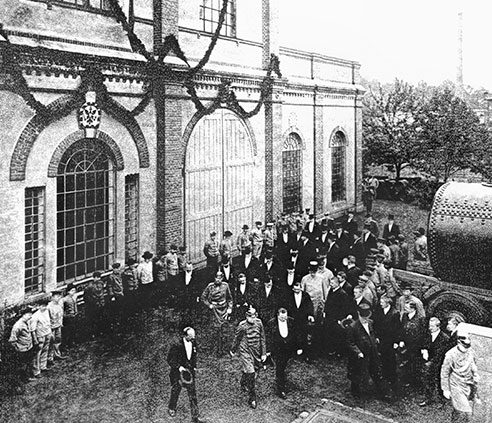

Experience & quality since 1862

Over 150 years of experience in the production of pressure parts for steam boilers.

2025

Meeraner Dampfkesselbau GmbH becomes part of the ENERGY TRANSITION CENTRE, S.L. group

2018

Relaunch of the brand MEERANER

2014

Meeraner Dampfkesselbau GmbH becomes part of the Mitsubishi Group

2007

Meeraner Dampfkesselbau GmbH becomes part of the Hitachi Group

2003

Manufacture of membrane tube walls from austenitic materials

1999

Manufacture of pressure parts with a steam output of 2600 t/h for large power plants

1997

Babcock Kraftwerkstechnik acquires Meeraner Dampfkesselbau GmbH

1993

Manufacture of pressure parts with a steam output of 1500 t/h for large power plants

1990

The newly named Meeraner Dampfkesselbau GmbH is acquired by Lentjes AG

1980

Manufacture of pressure parts with a steam output of 815 t/h for large power plants

1960

Steam boiler export to Egypt

1948

Dispossession of the company Dampfkesselbau F. L. Oschatz, change to VEB Dampfkesselbau Meerane

1906

Production of the first superheater in the region of Saxony, Germany

1899

First steam boiler export to China

1896

Production of the 1000th steam boiler

1862

The company´s registration in the German Trade Register as Dampfkesselbau F. L. Oschatz

Career & Job

Become a MEERANER!

Here is a list of all our current job offers. Become a part of our fast-growing traditional company. We are looking forward to your application!

We are looking for you!

Meeraner Dampfkesselbau GmbH – a company of the Premonor Group with registered office in Meerane/Saxony – offers their customers individual, innovative and high-quality products and services in the area of boiler, container and apparatus engineering as well as steam generators.

We shape the future together with our employees and customers all around the world.

Your application should contain the following documents:

- a personal cover letter

- a clearly structured curriculum vitae, which compiles your previous education and professional experience together with additional qualifications and skills

- copies of all relevant certificates (school, training and / or university certificates, certificates of professional activities, internships and additional qualifications)

Please send your detailed application, which we will treat confidentially of course, via e-mail to bewerbung@mdkb.de or by post to:

Meeraner Dampfkesselbau GmbH

Zwickauer Straße 94-98

08393 Meerane/Germany

Phone: +49 (0) 3764 53-0

Vacancies

Unsolicited application

Unsolicited application

We are looking forward to you and to your application. Even in case we do not seek to fill a vacancy in our company at the moment, which corresponds to your career and your wishes, we are always interested in qualified applicants and we will be pleased to receive your unsolicited application.

Location & Direction

How to get to us.

Everything began here more than 150 years ago: Our heart beats at Meerane, Saxony. With the location at the motorway A4 and at the federal highway B93, we are situated in a very favourable logistical position and are easily accessible. Furthermore, the airports Leipzig and Dresden are only about one hour by car away from Meerane.

Head Office

Zwickauer Straße 94-98

08393 Meerane/Germany

Phone.: +49 (0) 3764 53 0

Fax.: +49 (0) 3764 53-526

Mail: info@mdkb.de

Mit dem Laden der Karte akzeptieren Sie die Datenschutzerklärung von Google.

Mehr erfahren

Fairs & Conferences

See you there.

| DATE | EVENT | INDUSTRY | LOCATION |

|---|---|---|---|

| 07.10. - 08.10.2025 | KWTK 57th power plant technical colloquium | Power plant construction | Dresden/ Germany |

| 25.11. - 26.11.2025 | vgbe Thermal waste, sewage sludge treatment and fluidized bed combustion 2025 | Energy & waste incineration | Hamburg/ Germany |

| 28.01. - 29.01.2026 | BKAWE Berlin Conference on Waste Management and Energy | Energy & waste incineration | Berlin/ Germany |

| 04.05. - 07.05. 2026 | IFAT Munich 2026 | Ware, Sewage, Waste and Raw Materials Management | München/ Germany |

References

We are proud of it.

Our company has a long-standing tradition in boiler engineering, which is why we can only show you a short excerpt of all of our references. All reputable national and international power supply companies and power station constructors, industrial power stations, as well as local energy providers are among our main clients. Furthermore, we have been working with customers from the steel production industry, operators of waste heat plants, waste incinerators, biomass combustion plants and other environmental heat recovery plants.

2023

| Customer | Object / Site | Scope of supply / Products |

| MPE | Kusile (PL) | burner atomizer |

| Uniper | Maasvlakte (NL) | membrane walls T24 |

| MSK | Boxberg (DE) | eco |

| MPE | Huntstown (IE) | repair of old attemporator |

| DSD Power | Schkopau (DE) | spiral panels and flue gas recirculation |

| Crop Energies | Zeitz (DE) | dust arrestor |

| MPE | Düsseldorf (DE) | fuel nozzle |

| Aurubis | Hamburg (DE) | membrane walls with deflection bends |

| RWE | Eemshaven (NL) | membrane walls T24 |

| Turbo Technik | Irsching (DE) | attemporator |

| MPE | Gendorf (DE) | membrane walls and bundles |

| MAN | Mannheim (DE) | control valve plate |

| Martin AG | Dietikon (CH) | membrane walls |

| Iqony | Lauta (DE) | deflection bendings |

| Wulff & Umag | Symrise (DE) | membrane walls |

| MPE | Drax 3 (GB) | burners |

| DSD Power | Heyden (NL) | headers |

| HZI | München (DE) | membrane walls |

2022

| Customer | Object / Site | Scope of supply / Products |

| RWE | Neurath (DE) | membrane walls T24 |

| MPE | Drax (GB) | burners |

| PCK | Schwedt (DE) | boiler bottom |

| MPE | Mannheim (DE) | spare parts for boiler |

| DSD Power | Schkopau (DE) | superheater |

| Saale Energie | Schkopau (DE) | repair of old attemporator |

| MPE | BASF Ludwigshafen (DE) | spare parts for boiler |

| Turbo Technik | Reuter (DE) | outlet headers |

| Wulff & Umag | Stuttgart (DE) | membrane walls |

| MPE | Stockholm (SE) | spare parts for boiler |

| J. Christof | OMV Schwechat (AT) | membrane walls and headers |

| RWE | Niederaußem (DE) | black and white connectors |

| MPE | Offenbach (DE) | parts for rotary kiln |

| Feralpi | Riesa (DE) | reconstruction evaporator bundles |

| Steinserv | Kiel (DE) | headers |

| MPE | Ptolemais (GR) | spare parts for mills |

| DSD Power | Eisenhüttenstadt (DE) | boiler |

| Turbo Technik | Emsland (DE) | attemporator |

2021

| Customer | Object / Site | Scope of supply / Products |

| Leipziger Stadtwerke | Leipzig (DE) | blow-out operation |

| MPE | Abu Qir (EG) | boiler bottom with burner tubes |

| DSD Power | KW Heyden (DE) | attemporator |

| MPE | Rotterdam (ND) | wall penetrations |

| Etabo | Reuter West (DE) | outlet header |

| Elbe-Stahlwerke Feralpi | Riesa (DE) | reconstruction evaporator |

| Leipziger Stadtwerke | Piesteritz und Bischofferode (DE) | superheater exchange |

| MPE | Sasol (RSA) | burners |

| LEAG | Lippendorf (DE) | tee pieces X10CrMoVNb91 |

| Wulff & Umag | Chemnitz (DE) | membrane walls |

| MPE | Västhamnsverket (SE) | membrane walls and burners |

| Thyssen | Köln Godorf (DE) | transition pieces |

| Wehrle Werk | Kahlenberg (AT) | straight and bended membrane walls |

| AKS | München Nord (DE) | membrane walls with openings |

| MPE | VW Wolfsburg (DE) | oil piping |

| Borsig Service | Vynova (DE) | piping |

| MPE | Kuwait (KW) | automatic burner cylinder gate valve |

| Doosan Babcock Energy | Witzenhausen (DE) | membrane walls and headers |

| MPE | Turow (PL) | spare parts for mills |

2020

| Customer | Object / Site | Scope of supply / Products |

| MPE | Kuwait (KW) | ADS Burners |

| Borsig Service | OMV Schwechat (AT) | Header, Superheater tube bundles, Gas tight welded membrane walls |

| DSD Power | Lippendorf (DE) | Superheater tube bundles |

| Polytechnik | Ausserschwyz (CH) | Eco with steel construction |

| Leipziger Stadtwerke | Piesteritz & Bischofferode (DE) | Main steam valve, Bypass pipeline |

| MPE | Flensburg (DE) | Superheater-, Evaporator- and Eco bundle heating surfaces |

| Frenzelit | Wolfen (DE) | Compensator after gas turbine |

| Romonta | Amsdorf (DE) | Eco- and Superheater tube bundles/td> |

| MPE | Kozienice (PL) | Pulverized – Coal Burners |

| RWE | Neurath (DE) | Gas tight welded membrane walls T24 |

| Borsig Service | München Nord (DE) | Gas tight welded membrane walls |

| DSD Power | Schkopau (DE) | Superheater tube bundles |

| MPE | Rotterdam (NL) | Spiral membrane walls |

| Wehrle | Emmendingen (DE) | Gas tight welded membrane walls |

| Gerald Estel Anlagenmontage | Königs Wusterhausen (DE) | Superheater tube bundles |

2019

| Customer | Object / Site | Scope of supply / Products |

| EVN Wärmekraftwerke | Zwentendorf (DE) | Gas tight welded membrane walls |

| Etabo Energietechnik | Neurath (DE) | RH – Spray attemperator |

| Heizkraftwerk Silbitz | Silbitz (DE) | Gas tight welded membrane walls |

| Hitachi Zosen Inova | Hamburg (DE) | Boiler wall segments with bends for burners, manholes and measuring points |

| GE Power | Homburg (DE) | Headers |

| Borsig Service | Leuna (DE) | Spray attemperators |

| Gerald Estel Anlagenmontagen | Feralpi Riesa (DE) | Retrofit Eco tube bundle module |

| Borsig Service | Zypern (CY) | Tube bends |

| MHPSE | Laziska (PL) | Absorber plates |

| TRV Wesseling | Köln (DE) | Weld cladding boiler walls with various openings and headers |

| DSD Power Berlin | Schkopau (DE) | Membrane tube wall segments for hopper Unit A |

| WULFF & UMAG | Gent (BE) | Gas tight welded membrane walls |

| LEAG | Lippendorf (DE) | Membrane tube walls for boiler spiral |

| KSC Anlagenbau | Erfurt (DE) | Gas tight welded membrane walls |

| WULFF & UMAG | Korbach (DE) | Gas tight welded membrane wall elements |

| Etabo Energietechnik | Niederaußem (DE) | RH3 header and connecting pipes |

| Doosan Babcock Energy | Piesteritz (DE) | Tube bundle |

| PCK Raffinerie | Schwedt (DE) | Boiler wall parts with inner-grooved tubes |

| MHPSE | Sorfert 4 (DZ) | Industrial boiler and finned tube Eco |

| Borsig Service | Moorburg (DE) | Feed water pipes |

| Unic Systems | Frankfurt a.M. (DE) | Boiler drum |

| Wehrle-Werke | Malmö (SE) | Gas tight welded membrane walls, tube bends |

| Dow Olefinverbund | Böhlen (DE) | Component replacement on the waste heat boiler |

| Engie Services | Rotterdam (NL) | Tube bends |

| Etabo Energietechnik | Huckingen (DE) | Spray attemperator |

| 1Heiz Energie | Eberswalde (DE) | Manhole opening for boiler wall |

| Vattenfall | Moorburg (DE) | Tube bends and bottoms |

| MHPSE | Baosteel (CN) | Manufacturing of blast furnace gas burner |

| Standardkessel Baumgarte | Hamburg (DE) | bended boiler wall parts made of omega tube |

| Steinmüller Babcock Environment | Salo (FI) | Manufacturing of vertical and horizontal boiler passes |

| MHPSE | Ruhleben (DE) | Superheater tube bundles |

| Mercer | Rosenthal (DE) | Gas tight welded evaporator boiler bottom |

| Uniper Kraftwerke | Leverkusen (DE) | Header |

| Boilerworks | Lingköping (SE) | Pipe bends |

| Wehrle-Werke | Freiburg (DE) | bended membrane wall segments |

| LEAG | Boxberg (DE) | T24 membrane walls |

| DSD Power Berlin | Schkopau (DE) | Hopper membrane walls Unit B |

| STEAG GmbH | Hagen (DE) | Straight and bended boiler walls with openings |

| Uniper Kraftwerke | Wilhelmshafen (DE) | Gas tight welded membrane walls |

| MHPSE | Datteln (DE) | Manufacturing of pressure parts for a complete first boiler draught |

| Borsig Service | K & S (DE) | Live steam header |

| MHPSE | Kozienice (PL) | Pipe protection for superheater tube bundles |

2018

| Customer | Object / Site | Scope of supply / Products |

| Borsig | Neurath (DE) | Superheater-header and spray attemperator |

| MHPSE | Maasvlakte (NL) | Superheater tube bundles with suspension tubes |

| Stadtwerke Erfurt | AHK-Erfurt Ost (DE) | Replacement of suspension tube systems |

| Menk Schmehmann | Leipa Schwedt (DE) | Reversal- and superheater-header |

| Uniper | Leverkusen (DE) | Header for membrane walls |

| Borsig | Neurath Block F+G (DE) | T24 membrane walls |

| MHPSE | Shell Godorf (DE) | Preheater- und economiser-module with duct casing |

| Vattenfall | Moabit (DE) | Superheater tube bundles with suspension tubes |

| RWE | Neurath (DE) | T24 – Membrane walls |

| MHPSE | Datteln (DE) | Superheater tube bundles |

| STEAG | Salzbergen (DE) | Reversal- and superheater-header |

| RWE | Westfalen (DE) | Black-white connectors |

| HPE | Rotterdam (NL) | Wall passage through for vertical part of boiler |

| MHPSE | Sasol (ZA) | Burners |

| PCK Raffinerie | Schwedt DE2 (DE) | Membrane walls |

| Estel | Feralpi Risa (DE) | Retrofit of economiser-module |

| Mewes | Dordrecht (NL) | Membrane walls and headers |

| Velde | Graz (AT) | Membrane walls |

| Stadtwerke Leipzig | BMHKW Piesteritz (DE) | bundle heat exchangers incl. assembly |

| Unic Systems | Obernburg (DE) | high pressure-header and steam pipes |

| Svex NV | Beveren (BE) | Membrane walls |

| InfraServ | Höchst/Frankfurt (DE) | Membrane walls |

| Wulff & Umag | Karlsruhe (DE) | Complete boiler-body made of membrane walls |

| ZP-Rosenthal | Blankenstein (DE) | Membrane walls |

| DSD | Heyden (DE) | Membrane walls |

| MHPSE | Turow (PL) | Wear parts for coal mills |

| Uniper | Schkopau (DE) | Membrane walls |

| MHPSE | Huntstown (IE) | Attemperator |

| Unic Systems | Bergkamen (DE) | Membrane walls |

| AWG Wuppertal | Wuppertal (DE) | Superheater tubes |

2017

| Customer | Object / Site | Scope of supply / Products |

| Stadtwerke Leipzig | BMHKW Piesteritz (DE) | Preheater for secondary air incl. assembly |

| MHPSE | Datteln (DE) | RH 2 heating surface tubes |

| MHPSE | Ptolemais (GR) | Vapourseparator |

| KSC | Hamburg (DE) | Superheater tubing |

| Borsig | Neurath (DE) | Superheater and spray attemperator |

| Estel | Wiesbaden (DE) | Superheater tubing |

| Velde | Orlen Trzebinia (PL) | Membrane walls |

| Uniper | Schkopau (DE) | Membrane walls |

| HPE | Rotterdam (NL) | Wall passage through for vertical part of boiler |

| AWG Wuppertal | Wuppertal (DE) | Membrane walls incl. attachments and internals |

| Borsig | Niederaußem Bl. G (DE) | Headers, spray attemperator, connecting pipes |

| Velde Orlen | Trzebinia (PL) | Membrane walls |

| MHPSE | Kusile 8 (ZA) | Supporting tube suspension |

| MHPSE | Hamm (DE) | bulkhead collectors |

| Hülsenbusch | BASF Ludwigshafen (DE) | Boiler roof |

| Uniper | Bremen (DE) | Membrane walls |

| RWE | Niederaußem BL. K (DE) | Black-White connectors |

| 1Heiz Energie | Eberswalde (DE) | Boiler roof |

| Velde | Monheim 4 (DE) | Membrane walls |

| Doosan Babcock | Tornesch (DE) | Membrane walls |

| Velde | BASF (DE) | Membrane walls |

| HZI | Pirmasens (DE) | Membrane walls |

| RWE | Eemshaven (NL) | Connecting pipes |

| PCK Raffinerie | Schwedt DE1 (DE) | Wall passage through superheater and evaporator bulkhead |

| Velde | Hamburger Rieger (DE) | Membrane walls |

| MHPSE | Ulm (DE) | Economizer |

| Steinmüller Babcock Environment | San Sebastian K1 (ES) | Vertical trains 1-3 with grate edge pipes, horizontal trains 4-6 with Eco, evaporator and superheater bundle |

| Steinmüller Babcock Environment | San Sebastian K2 (ES) | Vertical trains 1-3 with grate edge pipes, horizontal trains 4-6 with Eco, evaporator and superheater bundle |

| PCK Raffinerie | Schwedt DE2 (DE) | Superheater, evaporator bulkhead, support tubes, evaporator bottom |

| Uhlig | Pfleiderer (DE) | Membrane walls |

| DSD Berlin | Schkopau (DE) | Membrane walls |

| Wehrle AG | Malmö (SE) | Membrane walls |

| Unic Systems | Pfleiderer (DE) | Headers |

| Uniper | Schkopau (DE) | Membrane walls |

| GE Power | Heusweiler (DE) | Spray attemperator |

| Uniper | Stockstadt (DE) | Superheater, Header |

| Svex Indaver | Beveren (BE) | Membrane walls |

| Stadtwerke Leipzig | Piesteritz (DE) | Secondary air preheater |

2016

| Customer | Object / Site | Scope of supply / Products |

| Unic Systems | Pfleiderer Gütersloh (DE) | Milling drum |

| PCK Raffinerie | Schwedt DE1 (DE) | Superheater, Evaporator bulkhead, support tubes, evaporator bottom |

| LEAG | Lippendorf Block S (DE) | Burner corners |

| Südzucker | Zeitz Werk Zeitz (DE) | Spray attemperator |

| LEAG | Boxberg R (DE) | Wall passages T24 |

| VKK | Smurfit Kappa (DE) | Membrane walls |

| 1Heiz Energie | Eberswalde (DE) | Economizer |

| ETABO | Niederaußem Bl. H (DE) | ZÜ3 Outlet header |

| MHPSE | Ptolemais (GR) | Membran walls upper part, Transition parts, Spiral walls, Hopper, Headers, Attemperator, Separator |

| MHPSE | Ptolemais (GR) | Vapour burner |

| MHPSE | Turow (PL) | Membran walls roof, Membran walls upper part, Transition parts, Spiral walls, Hopper, Headers, Attemperator, Separator |

| MHPSE | Turow (PL) | Pulverized coal burners |

| MHPSE | Kusile 8 (ZA) | Spray attemperator |

| MHPSE | Avedöre (DK) | Heat exchanger |

| MHPSES | Abu Qir (EG) | Boiler component |

2015

| Customer | Object / Site | Scope of supply / Products |

| MHPSE | Kusile 1-6 (ZA) | Header, T-Pieces, Connecting tubes, Spare parts |

| Infra Serv | Wiesbaden (DE) | Superheater |

| MHPSE | Turow (PL) | Membran walls roof, Membran walls upper part |

| MHPSE | Raghunathpur/Meja/Solapur (IN) | Pulverized coal burners Spare parts |

| MHPSE | Medupi (ZA) | Separators |

2014

| Customer | Object / Site | Scope of supply / Products |

| MHPSE | Solapur 2 (IN) | Transition part, Attemporators Separators, Start up vessel Pulverized coal burners |

| MHPSE | Meja 1 (IN) | Seperators, Start up vessel |

| MHPSE | Kozienice (PL) | Transition part, spiral walls, Burner openings, hopper, Headers; Upper part walls |

| MHPSE | Raghunathpur 2 (IN) | Pulverized coal burner |

| MHPSE | Meja 2 (IN) | Transition part, Attemporators Separators, Start up vessel Pulverized coal burners |

| Vattenfall | Lippendorf (DE) | Burner openings |

2013

| Customer | Object / Site | Scope of supply / Products |

| HPE | Medupi Block 5 (ZA) | Open pass |

| HPE | Medupi Block 6 (ZA) | Open pass |

| HPE | Solapur 1 (IN) | Transition part, spiral walls, burner openings, hopper, superheater headers |

| HPE | Meja 1 (IN) | Pulverized coal burner |

| HPE | Kusile 3 (ZA) | T-pieces and star distributors |

| HPE | Kusile 3 (ZA) | Start up vessel, separators |

| Borsig | Weisweiler (DE) | Headers with connecting tubes |

Contacts

Overview and contact details.

Management

Klein, Bernd

| Chief Executive Officer | ||

| Phone: | +49 (0) 3764 53-281 | |

| Fax: | +49 (0) 3764 53-526 | |

Finance & IT

Ellmrich, Steffen

| Head of Finance and IT & Authorised Officer | ||

| Phone: | +49 (0) 3764 53-345 | |

| Fax: | +49 (0) 3764 53-526 | |

Sales

Petzold, Jens

| Project Manager Sales | ||

| Phone: | +49 (0) 3764 53-273 | |

| Fax: | +49 (0) 3764 53-320 | |

Kühnert, Thomas

| Project Manager Sales | ||

| Phone: | +49 (0) 3764 53-253 | |

| Fax: | +49 (0) 3764 53-320 | |

Dabergotz, Frank

| Project Manager Sales | ||

| Phone: | +49 (0) 3764 53-251 | |

| Fax: | +49 (0) 3764 53-320 | |

Zucker, Oliver

| Project Manager Sales | ||

| Phone: | +49 (0) 3764 53-390 | |

| Fax: | +49 (0) 3764 53-320 | |

Porzig, André

| Project Manager Sales | ||

| Phone: | +49 (0) 3764 53-422 | |

| Fax: | +49 (0) 3764 53-320 | |

Severin, Steve

| Sales Representatives | ||

| Phone: | +49 (0) 3764 53-278 | |

| Fax: | +49 (0) 3764 53-320 | |

Purchase

Freitag, Martin

| Purchaser | ||

| Phone: | +49 (0) 3764 53-274 | |

| Fax: | +49 (0) 3764 53-320 | |

Kappler, Aline

| Purchaser | ||

| Phone: | +49 (0) 3764 53-252 | |

| Fax: | +49 (0) 3764 53-320 | |

Production & Manufacturing

Nührig, Ronny

| Production | ||

| Phone: | +49 (0) 3764 53-586 | |

| Fax: | +49 (0) 3764 53-573 | |

Welding Technology

Ritter, Michael

| Welding Engineer | ||

| Phone: | +49 (0) 3764 53-398 | |

| Fax: | +49 (0) 3764 53-573 | |

Logistics

Möhring, Frank

| Logistics | ||

| Phone: | +49 (0) 3764 53-389 | |

| Fax: | +49 (0) 3764 53-284 | |

Quality Management

Pätzold, Marcel

| Head of Quality Management | ||

| Phone: | +49 (0) 3764 53-396 | |

| Fax: | +49 (0) 3764 53-573 | |

Compliance

Our guide in ethical and legal issues.

Compliance for the Meeraner

It is the objective of Meeraner Dampfkesselbau GmbH to conduct all business relations in an ethical and professional manner. This includes compliance with legal and internal regulations, avoiding conflicts of interest and protecting the company’s assets and reputation. The company always takes into account customs, traditions and social values of the countries where it does business. Misconduct and workarounds are not in the interest of the company and will not be tolerated.

Code of Conduct

As group company of Premonor Group, our Code of Conduct contains important rules of behavior which help answering ethical and legal questions in daily business and in strategic decision-making processes.

As an international company, Meeraner Dampfkesselbau GmbH employs individuals from different backgrounds, nationalities and cultures. This diversity of talent and perspectives is one of our greatest assets. At the same time, however, PSS as a company must operate with a single corporate culture that enables it to compete successfully in the global market while maintaining its reputation as a company of high integrity and ethics. The Code of Conduct describes how Meeraner Dampfkesselbau GmbH companies and employees should conduct themselves.